| No. | Name | specifications | remark |

| 1 | Mixing system | 1. Model:js1000 2. type:Double horizontal shaft 3. Charging Capacity:1600L 4. Discharge Capacity:1250L. 5. Unloading height :4m 6. Motor Power:18.5×2 7. Mixing Blade, liner plate:wear resistant material System specifications: 1.Star type reducer js1000,High transmission efficiency, low heat,

strong reliability 2.Mixing Blade and liner plate is made by high chromium wear

resistant cast iron, Reasonable Angle design, good mixing effect,

fast speed, long service life 3.The four shaft end is equipped with a fully automatic oil sealing

system. 4,The discharge door is controlled by dual cylinder control, and

can be operated manually, without noise. 5,The multi-contact roller oil system is stable. | SICOMA brand |

| 2 | electrical control system | The electrical control system consists of computer host, monitor,

cabinet, printer, communication cable, weighing instrument, bridge

frame, etc. 1.Operation and management all in one, easy to operate. 2.The batching system is controlled by industrial integration. 3.The formula can be expressed in Numbers, easy for user

identification and dozens of recipes. 4.It has the function of error analysis and automatic detection. 5.In the absence of automatic control, the manual operating system

can still complete the control of the mixing station, such as

ingredients, stirring, discharging and so on. 6,The strong electric part of the system is self-contained, which

is completely separated from the weak current part, which improves

the anti-interference ability of the weak current and makes the

strong electric part greatly simplified and the maintenance is more

convenient. 7,Equipped with four screen monitoring system. System specifications: The main hardware used in this system adopts schneider/Siemens

products with advanced features, high reliability and beautiful

appearance. The console adopts industrial cabinet. | 1,printer:EPSON 2,monitor 19” 3,main electrical component :schneider/Siemens

|

| 3 | Lift system | The aggregate lifting system adopts the Bucket conveyor or belt

conveyor.

| 1,air cylinder: AKS brand |

| 4 | aggregate-weighing system

| Aggregate weighing system consists of: bone silo, rack, weighing

hopper, aggregate conveyor, sensor, etc. 1,aggregate bin (1)capacity:10m3×3 (2)discharge door:6sets (3) air cylinder:80×310 2,weighing hopper (1)capacity:1.2m3×3 (2)measuring type:cumulative measure (3)sensor:2000kg×4 (4) measuring accuracy:±1% 3,belt conveyor (1)belt model:800mm (2)belt speed:1.6m/s 4, rolling power:11kw 5,vibrator:0.5KW*2 description: the aggregate loaded to aggregate bins by wheel loader, there are

three bins, every bin has two discharge door, In order to achieve

the measurement of rough and fine. The weighing hopper is the three

positions on the belt, the aggregate discharge to the belt to

measuring by four sensors on the belt. The signals sent by the four

sensors are processed and sent to the microcomputer in the main

control room. |

|

| 5 | cement-weighing system

| cement-weighing system consists of: cement weighing hopper,

pneumatic butterfly valve and sensor etc. 1,cement weighing hopper: (1)capacity:650L. (2)weighing scale:0~1000kg (3)weighing accuracy:±1% 2,sensor:1000kg×3 3,pneumatic butterfly valve:DN300 description: The cement weighing device is fully sealed, and the weighing hopper

is measured by 3 sensors. The weighing hopper door adopts the

typical pneumatic butterfly valve, which is flexible and tightly

sealed. | l,sensor:Kemin brand 2,valve:shanghai brand |

| 6 | powder-weighing system

| powder-weighing system consists of weighing hopper, pneumatic

butterfly valve and sensor. 1,powder weighing hopper:: a)capacity:600L b) weighing scale:0~880 kg c) weighing accuracy:±1% 2,sensor:500kg×3 3,pneumatic butterfly valve:DN300 description: The powder weighing system is filled with a full sealing device,

and the weighing hopper is measured by three sensors. The weighing

hopper door adopts the typical pneumatic butterfly valve, which is

flexible and tightly sealed. | 1,sensor:qingdao brand 2,butterfly valve:shanghai kangwei |

| 7 | Water weighing system | Water weighing system consists of: water tank (customer own), water

pump, water weighing hopper, pneumatic butterfly valve, etc.. 1,water supply pump:3kW 2,water injection pump:3kW 3,weighing scale:400L 4,sensor:500kg×3 5,pneumatic butterfly valve:DN200 6,weighing accuracy:±1% description: Under the control of the control system, the pump will be pumped

into the water weighing hopper, and the pump will stop when the

sensor is measured to the preset value. When the water is

discharged, the pneumatic butterfly valve is opened, the discharge

pump is started, and the pump is pumped into the mixer. | 1,sensor: Kemin brand 2,water pump Shandong zibo brand 4,butterfly valve:Hunan brand |

| 8 | Liquid admixture measurement system | The admixture weighing system consists of: admixture storage box, admixture, admixture pump, pneumatic butterfly valve, sensor and so on. 1,weighing accuracy:±1% 4,sensor:100kg×1 5,pneumatic butterfly valve:DN80×1 description: With the control of the control system, the admixture pump pumped

out the admixture, and the pump stops when the sensor is measured

to the preset value. The pneumatic butterfly valve is opened when

unloading, so that the admixture flows to the water weighing hopper

and flows into the mixer with the water. At the same time, the

water pump continues to work on the circulating admixture,

stirring, in case the admixture is precipitated, the pump is

controlled by the microcomputer. | 1,admixture pump: Shandong zibo brand 2,sensor: Shandong qingdao brand 3,butterfly valve:shanghai kangwei |

| 9 | Air system | Pneumatic system consists of air compressor, cylinder, solenoid valve and gas circuit element. 1,air compressor:7.5 Kw 2,air tank:warranty one year, 0.1m+0.6 m3 description: 1,control the discharge door. 2,control the butterfly valve. 3,control the broken arch of the cement silo. 4, Control the mixer double door. | 1,Air cylinder: AKS 2,solenoid valve: YIHUA brand 3,air treatment Jiangsu brand 4,air compressor: Fujian brand |

| 10 | Main building | composed of ladder, platform, guardrail, steel frame and so on | |

| 11 | Screw conveyer | Cement screw conveyer, powder and powder admixture screw conveyer. (1)model:Φ219 (2)number:2 sets (3)delivery capacity:65t/h (4)motor power:11 kw description: 1,The powder conveying adopts the whole sealing device. The soft

connection between the outlet and the measuring bucket does not

affect the measurement accuracy. 2,The feeding port is universal ball joint, adjustable Angle

deviation and good sealing. The spiral blade has small clearance

and high transmission efficiency.. | |

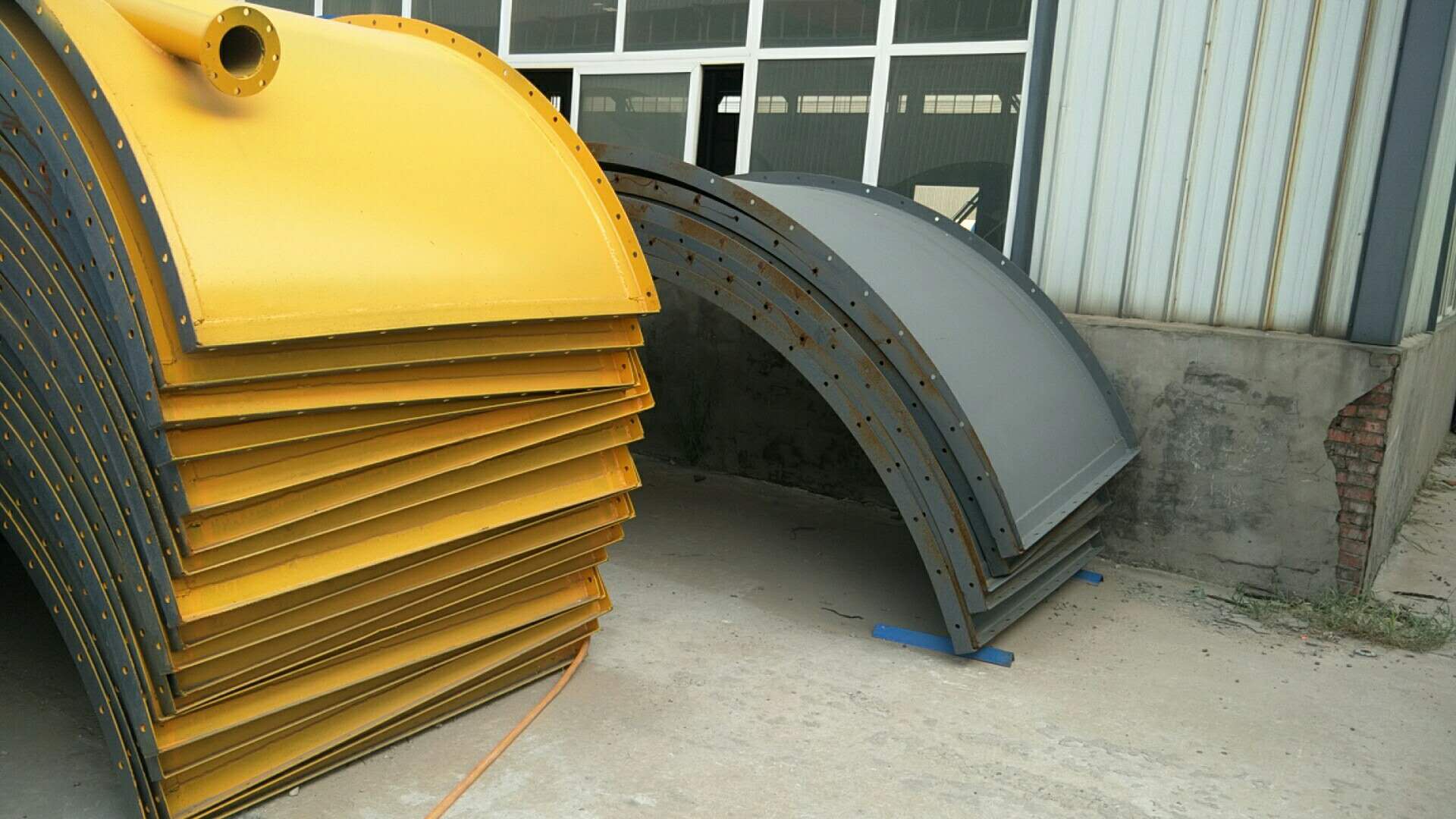

| 12 | Powder silo | 1)capacity:100T*2 description:The top of the powder bin is equipped with a dust

collector, which reduces the load pressure of the powder bin and

prevents the dust from contaminating the air. The broken arch

device is installed in the cone, combined with the gas road system

and control system, which can automatically break the arch of the

cement in real time, and also can break the arch manually. In order to save transportation cost, the powder silo usually made

by customers themselves. | dust collector:Changsha brand |

| 13 | Control room | It usually made on the site. The control room is spacious and bright. | |

| 14 | Total power | Around 85kW | |