HZS90 Stationary Ready Mixed Concrete Batching Plant

Powder measuring and supplying system

- Adoption of spiral conveyor, high-efficient and maintenance-free.

The powder measuring and supplying system consists of the silos,

spiral conveyor and powder measuring devices. The

powders (cement, coal dust, etc.) are filled into the storage silo

through bulk cement tank car. The silo top is provided with

dust collector, which feature good dust collection and easy

maintenance. In addition, the silo top is provided with pressure

relief valve and material level indicator. The automatic opening of

relief valves can prevent too high an in-silo pressure.

The level indicators can produce the actual materials level. The

silo bottom cone is provided with fluidisation pads so as

to break through arched powder. The silo bottom is provided with

hand-operated butterfly valves to facilitate maintenance

of the silos and spiral conveyor. When it is necessary to feed

powder into the mixer, the powder from the silo is conveyed

with spiral conveyor into the powder measuring devices (cement

measuring device, coal dust measuring device) for

measuring purpose. The spiral conveyor would not stop feeding until

measuring requirements are met.

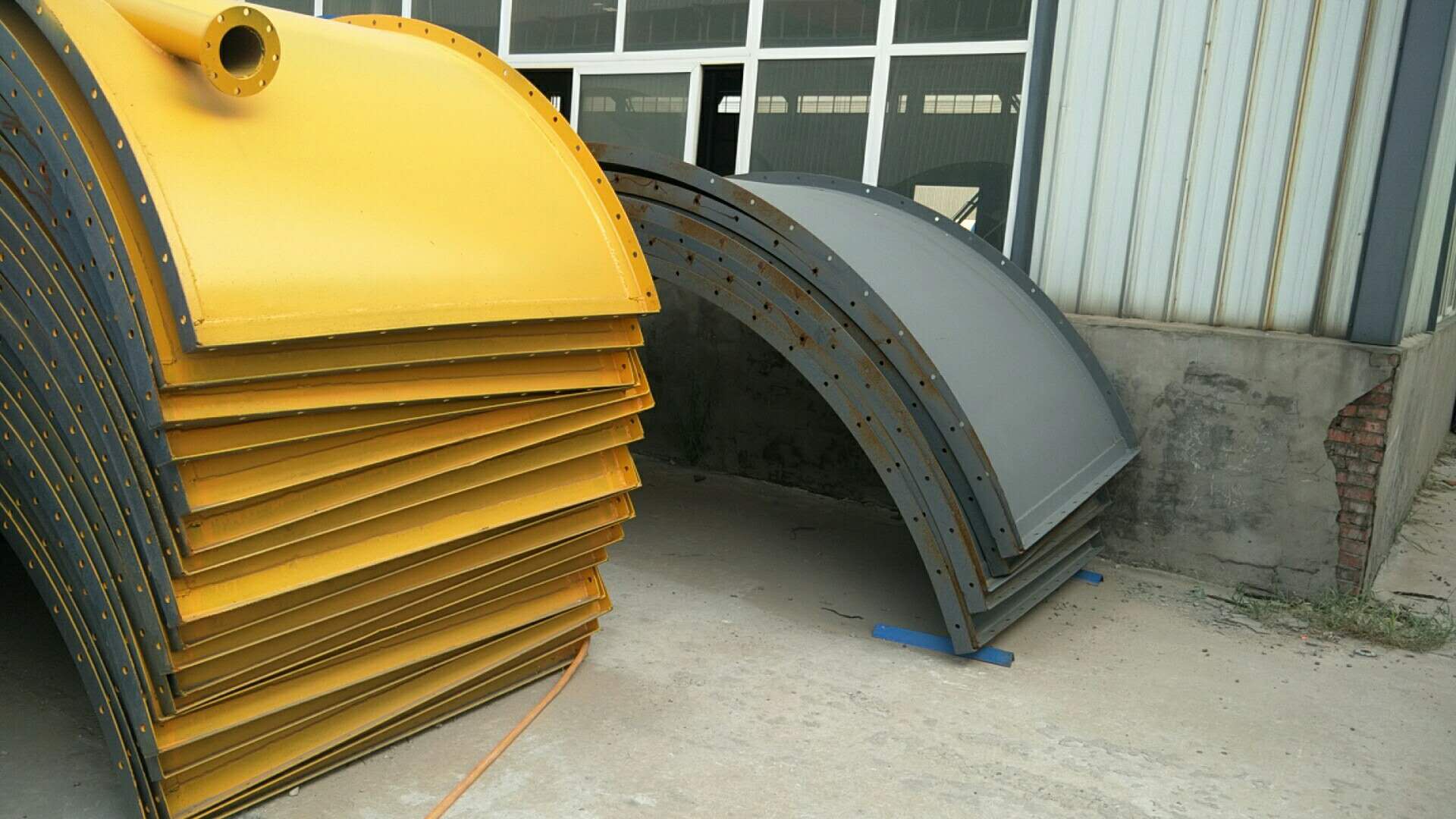

1. Silo

- With pressure relief guards

- Silo top with material level indicators

- Silo top with dust collectors

- Silo bottom with fluidisation pads

The silo is a container for storing cement, coal dust and the like

similar kind of powder. Its upper portion is provided with material

level indicators and its lower portion with signal lights. When the

silo has been fully filled, signal lights in the control room and

on the

silo lower portion will be on, warning simultaneously. At this

time, powder must be stopped conveying immediately. The silo upper

portion is provided with dust collectors to prevent dusts from

entering the atmosphere, causing environment pollution. The silo

upper

portion is also provided with pressure relief guards. When the

cement tank car fills cement into the silo and causes excessive

pressure

in silo, the guards will open automatically for pressure relief to

avoid accidents. Prolonged operation of dust collectors will lead

to

decrease filtering efficiency of filter cores. And exhausting

capacity will be decreased too. This will cause excessive pressure

in

silo during cement conveyance, leading to relief guards start-up.

Therefore dust collectors must be checked and cleaned at a regular

interval to change filter cores just in case.

Special attention

-Cleaning the filter cores at dust collectors can be on the

responsibility of a designated person, who must start up the

vibrating motor

after charge completion. The running duration of the vibrating

motor must not be longer than one minute.

-Each charge duration must not be too long. No longer than one hour

is preferable.

-Once half a year filter cores must be checked for dirty materials.

The filter core must be taken down and cleaned if too dirty.

The silo bottom is provided with fluidisation pads. The air

pressure for arch breaking is controlled at 0.1~0.3Mpa. The manual

butterfly valve is provided between the silo bottom and spiral

conveyor to facilitate maintenance of the silo and spiral conveyor.

2 .Spiral conveyor

- Variable pitch-designed blades with high-efficient conveyance

- Specially designed for powder conveyance

- Maintenance-free middle supports

The spiral conveyor is the equipment to convey the powder from the

silo onto the powder scale by means of continuous spiral

blades.

3 Powder (cement, coal dusts) measuring device

- sensors to ensure measuring accuracy

- Large diameter butterfly valves with high efficient charging

- Compensation of unbalanced sensors

After the powder hopper (cement hopper, coal dust hopper) has

contacted the sensor via connection seat, sensor signals will be

output and amplified and compared with pre-set values. When the

powder has reached pre-set values, the spiral conveyor will stop

powder feed. When the mixer requires powder feed, the butterfly

valve will open and powder will be discharged directly into the

mixing drum of the mixer. After discharge completion, the powder

scale will start at once the next measuring operation, thus making

full use of the mixing time and reducing the mixing period. The

powder scale hopper is provided with two powder inlets. The powder

from different silos can be placed onto the scale via start-up of

different powder spiral conveyors. The cement scale hopper and coal

dust scale hopper are both provided with vibrators to facilitate

powder into the mixer. For details, refer to 4.10 Electronic Scale